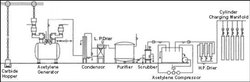

#Acetylene-Gas-Plant-manufacturers #Bosco-India An acetylene gas plant is a facility that produces acetylene gas through the chemical reaction of calcium carbide with water. Acetylene gas, also known as ethyne, is a highly flammable gas that is commonly used as a fuel for welding, cutting, and brazing operations, as well as for various industrial and chemical applications. Here are some key components and processes involved in an acetylene gas plant: Calcium carbide handling: Calcium carbide, a solid compound, is the primary raw material used in the production of acetylene gas. It is typically stored in silos or containers and fed into the plant in a controlled manner to prevent accidental ignition or reaction with moisture. Carbide-to-water reaction: Calcium carbide reacts with water in a controlled manner to produce acetylene gas and calcium hydroxide as a byproduct. This reaction is highly exothermic and requires careful temperature and pressure control to ensure safe and efficient production of acetylene gas. Gas purification: The generated acetylene gas is typically purified to remove impurities, such as moisture, hydrogen sulfide, and phosphine, which may be present in the gas stream. Purification processes may include scrubbing, filtering, and drying to meet the required gas quality standards. Gas compression and storage: Acetylene gas is highly unstable and requires careful handling and storage. It is typically compressed and stored in special containers, such as acetylene cylinders, which are designed to safely store and transport the gas under high pressure. Safety systems: Acetylene gas plants are equipped with various safety systems, such as gas detectors, pressure relief valves, flame arrestors, and ventilation systems, to ensure safe operation and prevent the risk of fire, explosion, or other hazards associated with acetylene gas. Maintenance and safety procedures: Acetylene gas plants require regular maintenance and inspection to ensure proper functioning and safety. Proper safety procedures, such as handling and storage guidelines, emergency response plans, and training for plant operators and workers, are crucial to prevent accidents and ensure safe operation. It's important to note that the production and handling of acetylene gas can be hazardous due to its highly flammable and reactive nature. Proper safety measures, compliance with applicable regulations, and adherence to industry best practices are essential for the safe operation of an acetylene gas plant.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

#Acetylene-Gas-Plant-manufacturers #Bosco-India...

2023-04-13T05:05:26

#Acetylene-Gas-Plant-manufacturers #Bosco-India An acetylene gas plant is a facility that produces acetylene gas through the chemical reaction of calcium carbide with water. Acetylene gas, also known as ethyne, is a highly flammable gas that is commonly used as a fuel for welding, cutting, and brazing operations, as well as for various industrial and chemical applications. Here are some key components and processes involved in an acetylene gas plant: Calcium carbide handling: Calcium carbide, a solid compound, is the primary raw material used in the production of acetylene gas. It is typically stored in silos or containers and fed into the plant in a controlled manner to prevent accidental ignition or reaction with moisture. Carbide-to-water reaction: Calcium carbide reacts with water in a controlled manner to produce acetylene gas and calcium hydroxide as a byproduct. This reaction is highly exothermic and requires careful temperature and pressure control to ensure safe and efficient production of acetylene gas. Gas purification: The generated acetylene gas is typically purified to remove impurities, such as moisture, hydrogen sulfide, and phosphine, which may be present in the gas stream. Purification processes may include scrubbing, filtering, and drying to meet the required gas quality standards. Gas compression and storage: Acetylene gas is highly unstable and requires careful handling and storage. It is typically compressed and stored in special containers, such as acetylene cylinders, which are designed to safely store and transport the gas under high pressure. Safety systems: Acetylene gas plants are equipped with various safety systems, such as gas detectors, pressure relief valves, flame arrestors, and ventilation systems, to ensure safe operation and prevent the risk of fire, explosion, or other hazards associated with acetylene gas. Maintenance and safety procedures: Acetylene gas plants require regular maintenance and inspection to ensure proper functioning and safety. Proper safety procedures, such as handling and storage guidelines, emergency response plans, and training for plant operators and workers, are crucial to prevent accidents and ensure safe operation. It's important to note that the production and handling of acetylene gas can be hazardous due to its highly flammable and reactive nature. Proper safety measures, compliance with applicable regulations, and adherence to industry best practices are essential for the safe operation of an acetylene gas plant.

2023-04-13T05:05:26

Keywords

- fuel

- fire

- risk

- silos

- ethyne

- cutting

- workers

- welding

- moisture

- facility

- required

- training

- filtering

- scrubbing

- accidents

- adherence

- explosion

- byproduct

- impurities

- inspection

- compliance

- gas stream

- Bosco-India

- high pressure

- gas detectors

- other hazards

- key components

- solid compound

- safe operation

- water reaction

- reactive nature

- plant operators

- flame arrestors

- Gas compression

- hydrogen sulfide

- pressure control

- careful handling

- Gas purification

- controlled manner

- calcium hydroxide

- chemical reaction

- storage guidelines

- special containers

- brazing operations

- proper functioning

- various industrial

- accidental ignition

- careful temperature

- ventilation systems

- acetylene cylinders

- regular maintenance

- efficient production

- Acetylene gas plants

- primary raw material

- chemical applications

- gas quality standards

- Purification processes

- various safety systems

- Proper safety measures

- pressure relief valves

- applicable regulations

- industry best practices

- Calcium carbide handling

- Proper safety procedures

- emergency response plans

- Acetylene-Gas-Plant-manufacturers

Search on this site

Have any question or need any business consultation?

Have any question or need any business consultation?

Contact UsBosco India

Submit Your Enquiry